I dont know why they have to lie about it. At $5/8ft board you’d think I paid for the full 1.5. Edit: I mixed up nominal with actual.

Shouldn’t the normal size be 2? Given, well, the name?

You’d think so, but no.

Short story is the ‘nominal’ size is the size before going into a planer to smooth the faces.

Yes, it makes little sense, like many things related to construction stuff.Yeah sorry. The tree was originally 50ft tall so we call the pieces that. But you only get 3ft

Is like buying 1200lbs steaks because that’s what the cow weighs before it gets parted

Better example would be raw vs cooked weight of a 1/4lb paddy.

Exactly. Because it is easier to weigh the correct amount before cooking than find out you were wrong after.

But you should probably be feeding Patrick more.

That’s a very small area to grow rice in.

Or a very offended Irish person.

Leprechaun

They prefer vertically challenged…don’t be insensitive

A full bag of crisps, but a third is just air

It’s not a 2x4 it’s a “2x4.”

And if you’re a fan of quotation marks you could call it a “2"x4”."

You have to escape the quotes…

“2\“x4\”” or use differing quotes ‘2"x4"’

I think this is an excellent time to point out that curl quotes (“ ”) are what are typographically used for quotations and apostrophes and hash marks (" ') are what are used for feet and inches. So it would look something like:

“ 2"× 4’ ”

(Spacing is still a bit ugly, I’d kern me some quote marks)

In CSV, you escape a double quote with a double quote.

Or use tsv or xsv and never quote a field again.

Sometimes we don’t get to pick what libraries and data formats we work with.

Especially with legacy systems and customer requirements.

In CSV you do whatever the fuck you want, and afterwards you delete the file cause CSV is trash and no one should use it.

You did that on purpose, you misanthrope.

deleted by creator

[Object][Object]

nominal

deleted by creator

This one of those things that sounds correct, but isn’t even remotely true. Like not at all, not even based on anything even.

Wall finishes varies in thickness wildly, and the milled wood also varies in final dimensions depending on moisture content.

Their comment made me almost consider posting an emoji on Lemmy.

The singular is emojus.

Dammit I had to look it up. It’s sheep, sheep.

Hoist on my own petard I was

Wall finished vary in thickness wildly

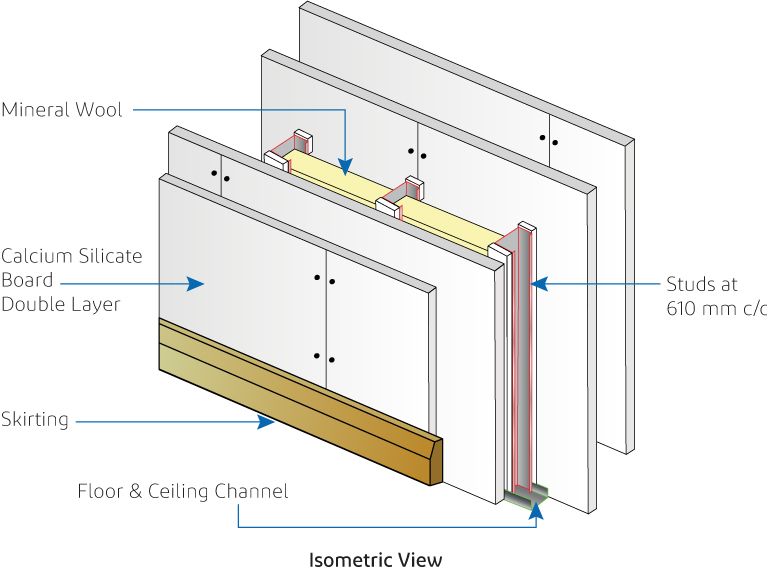

When I was designing kitchens, I and literally everyone in the construction industry around me all assumed that drywall was 1/2”

Fire rated partition wall? 2 layers of 5/8 each side for a total thickness of 6”

Not to mention the other side already needs a finish making it 4-1/2 already if they are both 1/2 claddings.

Come to think of it I think we were modeling it as 3/4 on each side, because I seem to remember the 3.5” 2x4 stud becoming a full integer thickness with drywall on both sides

Factually incorrect; the board is 2 inches by 4 inches (or whatever the marked dimension is) when rough sawn. After kiln drying and milling, it will be 1.5" thick and 3.5" wide. It still took 2 by 4 inches of the tree to make so that’s what you pay for.

Do I get the sawdust in a bag with it?

Maybe, if you ask the sawyer nicely.

Is his name Tom?

He gets high on you

The two-by-fours at your local home center are not 2 inches thick or 4 inches wide…not anymore at least. They spent several weeks at that size though. The sawmill cut them to that size to stack and kiln dry, and then when removed from the kiln they are then milled straight and square. Used to be they would sell the rough stock to carpenters who would do the milling themselves, but then they figured out that the railroads were charging them a fortune to ship a lot of wood that was going to be ground to sawdust anyway, so they started milling the boards before shipment. Same amount of construction lumber arrives at the construction site and it took less fuel for the locomotive to deliver it.

they are then milled straight and square

Lol. Trying to find lumber that’s straight and square is a pipe dream these days.

It was straight and square when it was milled. Problem is that the big box stores cut corners during the kiln drying phase, so the boards have a ton of moisture still in them. As that dries, the boards twist and cup.

Plus poor protection from the elements at each storage step, which means rapid temp changes, which also causes wood movement.

Go to a local lumber yard. They tend to do a better job at kiln drying. You’re still going to have warped boards, but far fewer in my experience.

Yeah, once I get my garage sorted out (and buy a jointer or make a Jig for my planer) I’m going to start getting rough cut lumber and finish it myself.

I tried the sled with shims on my thickness planer. It worked, but it was certainly a pain in the ass and unwieldy due to weight and length.

Picked up a 6" bench top jointer. Not great at long boards due to length of the feeds. Picked up some roller stands hoping that would be close enough, but I moved and the garage needs a lot of work before I can try them out.

If you can pick up a full floor sized jointer and have room for it, you’ll save yourself several headaches if you plan on jointing a ton of rough cut lumber.

I have to talk to someone at the lumber yard though …

I’ve had better luck at a real lumber yard, instead of the big box stores.

It’s the same 10 pieces on the top of the pile for weeks. Everyone is reaching for the pieces under. As long as it’s not 2x2PT

Which is why I buy stock rough sawn and mill it myself.

That’s my plan once I find a used jointer for sale.

if you own a thickness planer, you don’t immediately need a jointer. You can flatten a face with a sled and shims in the planer, and joint edges a frillion different ways. I have a jointer and sometimes I use my router table for edge jointing.

Lumber is weird because it has been industry standard to lie about dimensions since before the US existed so it’s just kinda a thing they get to do

No its not Maybe in the US? At least here, it is and has to be, very precise especially when it comes to industry quality. It is precise down to the mm!

Yeah but they measure in feet and cheesburgers.

And lies, don’t forget the lies

Alternative facts, thank you very much

In bullshit, which is itself an imprecise metric.

How does that work when wood varies due to moisture content? If they give precise mm measurements, only 20% of boards will meet those criteria.

All they are giving is the planned dimensions instead of nominal in mm form, it’s still not precise, it can’t be.

Construction lumber, especially pressure treated lumber, is sold so wet I don’t think it really matters. I’ve actually never tried to calculate wood movement for construction lumber because who the fuck cares? But for furniture lumber which is dried to between 6 and 14% moisture, there is a formula:

width of the board in inches x percentage of moisture change * expansion coefficient for a particular species.

Yellow pine (extremely common construction lumber) has an expansion coefficient of .00263. A 2x4 (actual dimension 1.5" by 3.5") that undergoes a 4% moisture content change will grow/shrink 3.54.00263 = 0.03682 inches, or just over 1/32". That’s in width; it’ll vary by less than half that in thickness. Wood basically doesn’t move along the grain; the board won’t get appreciably longer or shorter.

Maybe they mill, store, and sell under the same moisture conditions?

Also, how big is the difference in size and moisture for the same piece of wood? I would expect that moisture is usually not higher than 90% and not lower than 10% or something like that, but don’t know how it really is

Once it leaves the mill they go to various stores and regions with different conditions. Some places store them inside, others outside.

Once I buy it at the store and take it the site, it’s now different from the store. You should acclimate all lumber for 48 hours before using it as well, this is so the wood doesn’t swell or shrink more after installing it.

A 2x10 can be anywhere from 9-1/2 to almost 8-1/2 depending on final site conditions.

So, more than 10% difference, that’s enough to be a problem, indeed

A yellow pine 2x10 might move a tenth of an inch, not a full inch.

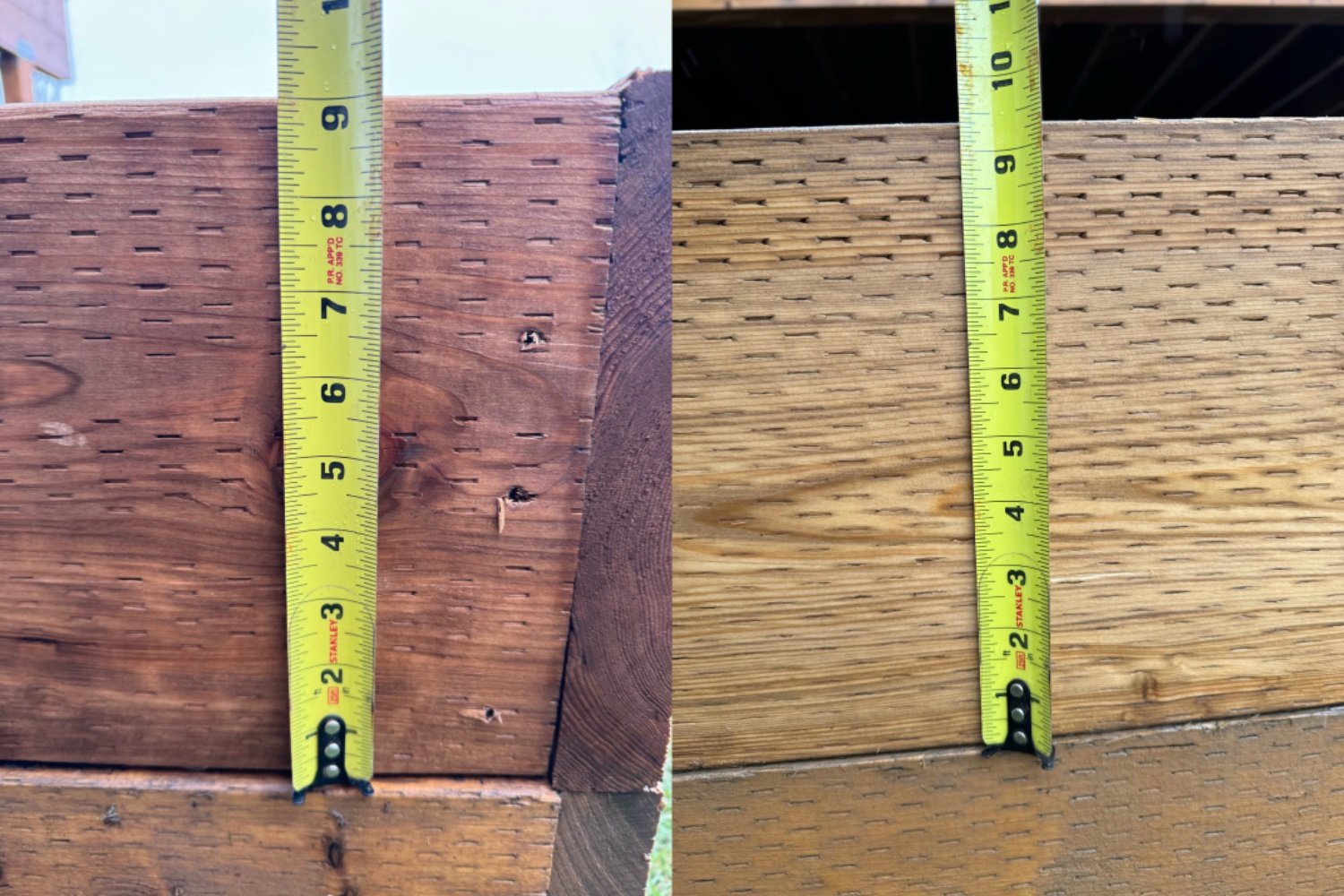

These were bought at the same time and are both 2x10 installed a couple days ago. You can even see the difference in the connection in the picture.

Over 3/8 of an inch and they both still need to dry.

Bullshit. Wood expands and contracts so ther is no way you can be precious down to the mm.

That’s why the standards specify the moisture content of the wood as well as the dimensions. This is even the case for US standards.

I’ve not really encountered this wood expanding and contracting thing. Are you sure?

Absolutely sure. It’s not really a factor in construction because of how the structure is engineered, but woodworkers have to constantly think about it.

Wood expands and contracts across the grain, but not so much along it. If you take a board that has been in a dry environment, put it in a humid environment, and allow it to acclimate, it will increase in width and thickness but not in length. At the microscopic level, wood is kind of like a bunch of ropes glued together with sponge, as it soaks up water the sponge wants to expand but the ropes don’t let it expand along their length.

Us woodworkers have to think about that when building things like doors, which might fit fine in the winter and then stick in the summer. It’s why we build frame and panel doors like this:

The large panel in the middle can expand and contract so much that it might be a problem, so we literally put it in a box. The outer dimensions of the frame are made mostly of the length of boards so it won’t expand and contract much, and the panel rests in a groove in the frame, not nailed or glued in place so that it can safely expand and contract as it wants to.

Attaching wide boards end-to-face can even present a situation where the boards want to move in different directions and they’ll eventually break each other.

You can even calculate the amount of wood movement given the species, of the wood, the dimension of the board and the amount of moisture change, you can read about it here.

You aren’t serious are you…?

Exaggeration

Realistic answer

Boards can shrink and grow due to moisture.

True, but the amount they shrink and grow across the grain tends to be proportional. A 2x4 is very rarely measurably different from 1.5"x3.5", but a 2x10 (like you’ve shown) is 1.5"x9 1/4" but is often anywhere between 9 1/8" to 9 3/8"

That’s crazy, how can you make a profit if you give the customer the exact measurement? You have to saw a bit off and pad your earnings!

That’s not why there’s a nominal size vs actual size.

It’s not exactly a lie, just a standard. Nominal board sizes were based on the unfinished lumber size. Another 1/4 inch is taken off each side to get a smooth surface that makes it easier to work with.

Here’s an old image (reddit warning)

that shows the rough cuts of boards from a log. When they look at a log, they determine how many of each size they can get from it, and at that point, a 2x4 is 2 inches by 4 inches.

Why does the consumer need to know the dimensions at harvest when it’s been processed multiple times?

That’s like calling an 4oz can of evaporated milk a gallon because it came from a gallon of milk before processing (I have no clue on the ratio)

I it’s like calling a quarter pounder a quarter pounder. You are not getting a quarter bound of burger after cooking.

And here I am thinking that it was a burger for reeeeally hungry people. No delusion anymore, it seems

I agree with this. Use whatever system you need or want internally, but there’s no reason to force whatever archaic or industry system onto a consumer. Logcutters also use a 1"=1/4 system and that is how they sell wood. A piece of wood that is 2" thick is sold as 8/4. Not 2". I get that they have their system but it seems dickish to force the consumer to use that system. There could be a good argument for it, but I’ve not heard one beyond “what, can’t you do math?”

but there’s no reason to force whatever archaic or industry system onto a consumer

Sure there is. Look up the concept of a “standard” if you don’t understand the reasons.

Standards only work when they don’t change

It’s like a 1/4lb paddy being a different weight before and after cooking. They can’t tell you the final weight, since it’s always going to be different. Same with wood.

The woods final actual dimensions can vary, so they tell you its original size.

A 2x10 can be anywhere from 9-3/8thick down do 8-3/4 depending on how it dries.

I get that. But this is for kiln dried wood. And this particular issue I’m bitching about isn’t about net loss. It’s selling wood using an internally useful measuring system instead of how the consumer would actually think about it. It’s adding needless complexity, in my mind, when there’s enough factors to consider.

What? The final dimensions of kiln dried wood can still vary. If they say 1-1/2 and you grab one that’s 1-3/8 you get a post like this.

So you say the original size, no one needs to do any math (what complexity are you referring to here?) since the final dimensions will always be different once acclimated at the site they will be used.

The consumer (people who work with lumber) knows how the system works. You don’t, because you don’t work with lumber.

If the boards were precisely measured in mm and binned accordingly, it would help no one because all construction techniques developed for use with lumber account for dimensional inaccuracy.

Building and working with lumber is different than working with manufactured materials like plywood or whatever.

You can buy planed or unplaned wood. Called “rough” lumber which is the nominal size instead. Usually only for pressure treated lumber, but it’s available in regular too.

They don’t, but every plan and instruction going back a looong time refers to things that way.

Essentially, where they make the wood calls it a 2x4. So the places that process the wood calls it a 2x4, and so on.

The kilning and planing process used to be much less regular, so if you used actual, you couldn’t buy four 1.5x3.5s, you’d get a 1.6x3.4, a 1.3x3.9, and so on.The only consistent way to refer to it was the original sawmill size, and people who built things knew you had to measure the actual size of each piece of wood, or just accept the slop.

We got better at planing and kilning, and eventually the actual size was standardized. We still had all those plans and bills of material referring to things by their nominal name, to say nothing of the actual builders and engineers who were both used to the nominal measurements and didn’t think it was necessary to change. So stores kept selling things by the name people expected when they were looking for products.

Most stores now label in both nominal and actual to accommodate for people who don’t know this, since buying lumber and building things isn’t as regular occurrence for a lot of people as it once was.

The consumer doesn’t need to know it. The lumber mill does, and the people responsible for warehousing and logistics, they use nominal sizes because saying “two by four” is easier than “one point five by three point 5.”

The consumer doesn’t need to know the dimensions at harvest. But the lumberjack and the sawyer do. They care about how much of the tree was needed to make a particular board, not how much board the customer ended up with.

its just easier to call it a two by four “yeah I gotta go out and get some 1 and a half by three and a halfs”

at that point, a 2x4 is 2 inches by 4 inches.

From my understanding, as tools have gotten more precise, the raw boards have gotten slightly smaller to reach the same standard size with less waste. So, 2x4 doesn’t even refer to modern unprocessed 2x4s, but rather a hypothetical unprocessed 2x4 at some point in the past.

That wouldn’t surprise me, but also the standard has been around for so long, changing the size of standard lumber is probably harder than changing the manufacturing process (which is likely automated and computer controlled anyway).

Not entirely true. I lived in a house that was just over a century old. The framing was exactly what it said it was, a 2x4 was 2” by 4”. Same for all the structure. These were mill cut, but still pretty clean. It was WW2-ish and after that we started to get planed lumber that gave us 1.5x3.5. It wasn’t even until probably the early part of the 1900s that lumber started to become “dimensional”, as in the standard sizes we know of today.

How could you use bundle when Business is the collective noun?

What are you talking about

A group of Ferrets is called a Business, or Busyness

This, my friend, is no mere “group” of ferrets. It is a horrific amalgam of a quantity greater than 300, bound together with simple twine in a structure of horrific dimension in a way that could only have been conceived by a mind twisted in reckless disregard to even a most basic understanding of the nature of our world.

As if american measurements have ever made sense. Look up how they measure screws or wires and despair.

Or shotgun shell sizes and loads.

“It all started in 1840 when the dram was a common unit of measurement…”

And they all had onions on their belts as was the style at the time.

Five bees for a nickel.

Expect for the .410 gauge. That one is a caliber, because reasons

It’s a wonder they manage to build anything. They have pocket calculators dedicated to the building industry. It’s surreal.

Not everyone

Some people are gods when it comes to metal math

🤘🏻

every house I’ve lived in has had something fucked up in it. Even if you have one guy doing everything correct, you have 20 other contractors coming in that can’t do basic addition and subtraction, let alone fractions.

I don’t think you’re implying this is exclusively an American issue or anything but that’s just the nature of construction unless you’re paying top dollar for accuracy when it matters.

I’ve been on a hundred or more construction sites and I’d confidently wager that most houses don’t match the plans perfectly because of unforseen reasons…equipment changing due to lead times, electricians running their conduit in the wrong stud bays, etc. I’ve had to do a lot of creative problem solving and design modifications are inevitable. That’s the only thing I really miss from my old career

Even when you are paying for accuracy… I went to a home once for someone who paid for the builders to get everything perfect; the walls were crooked and warped like every wall I’ve ever seen.

I’m just saying it doesn’t matter if one guy is really good because on projects that require multiple people a good team is all that matters. As far as uniqueness to the US vs everywhere, its probably worse here in the US but we have a lot of checks for extreme fuckups so we tend to just have a lot of low-mid tier fuckups. The big fuckups are when somebody lies on their expertise (like that university post tensioned beam bridge that fell in florida)

I am in chemical and material handling stuff and it’s the same. What amazes me is when the project manager can’t allow slack where slack is perfectly fine and allows slack where it isn’t.

One guy I will never forget had endless meltdowns about tiny tiny stuff in software and completely forgot that water pipes need heat tracing until the insulation was already installed. Whole project, multi tens of millions of dollars, died because of that. On the plus side before it died the password on the HMI was 8 characters long and required a number and a punctuation symbol.

Part of that is that you need to work hard to find good people who do good work.

The other issue is that all the skilled works are either old or dead. The young guys aren’t the same type.

At a societal level young people arent getting the benefits of their work. We’re getting what is paid for. They’re paying those old guys pensions+benefits but their own has been cut to the marrow. Consumers pay isn’t going to them. And good fucking luck to any of them trying to start up against behemoths both local and national that can nip them in the bud before they become competitive.

What I find is culture drives them out. I am pushed a lot to take away all decision making ability from the techs and electricians. This command-and-control organization system. Anyone who can change employment does and I don’t blame them.

Treat people like they are worthless and they leave. No surprises there.

My parents just had a house built last year and there is so much shit wrong. The biggest thing I found is one of the alcoves on the side of their fireplace is a full 1.5" wider in the front than the back. You don’t have to measure to see it. How the fuck the guy who did the framing, or the guy who did the drywall, or anyone else walking past that fucking thing didn’t notice I have no idea. They sold their nice old house for that pile of shit and it’s not even better even if you ignore all the problems. It pisses me off so much because I told them this was going to happen.

How do they measure despair?

The European wire gauge system makes no sense. There I said it. I don’t need to know the O.D. of the wire, I need to know the amp rating. The O.D. only becomes an issue for bending radius and there is a chart for that as well. Nothing is stopping some a**hole from making a wire almost completely out of plastic that has the O.D. of a typical 14AWG but can’t carry any serious amount of current under the European system. Under the AWG you always know what the current capacity is.

And while we are at it, you might as well standardize your wire sizes based on copper. You are never going to use anything except copper. So your units should reflect the material. I am building a chemical skid, that has nothing to do with the distance between the equator to the north pole.

Also when is the last time you were running wires that you needed a mm of precision? Meanwhile a fraction of an amp really does matter. So should not the thing that does matter be reflected in the product?

European wire gauge is not the outer diameter. It is the cross section of the conductor inside the wire in mm^2. It is the same system AWG uses (they are directly correlated) with the added benefit that the numbers make sense (10mm^2/AWG8 wire has 4x the cross section of 2.5mm^2/AWG14 wire, so a quarter of the resistance of the thicker wire and thus roughly double the current capacity).

How does 16, 14, or 12 AWG tell you anything about ampacity?

You use the chart. How does mm of a wire, including insulation, tell you ampacity? As I said it is easy to imagine a thick wire that can carry almost no current. You can’t pull that crap with AWG system. It tells you the single most important fact, how much current a wire can carry. There is no incentive for wire manufacturers to cheat the system since a thicker insulation wire just means more cost for them.

Which ties in nicely with the other charts. Tell me how much power you need a motor to deliver and what I have to deal with and I can tell you exactly what wires to use, it’s bending radius how thick it is etc. None of which I can do in the CE system.

Ironically outer insulation does impact conductor ampacity, because the rated continuous vs peak loads depend on the heat resistance rating of the insulation.

I honestly can’t tell if you’re doing a bit or are actually serious.

Sounds like a you problem.

The convention is 2" before milling. Milling takes off 1/4"on each side, so the result is 1.5".

Is this a joke? (I know it isn’t).

Why would I want to know the dimensions of the unfinished product? I’m not a construction worker, so honestly is there any reason?

I can only think it was when the lumber mill was the dictator of terms. That’s what they put out, so that’s what it was.

Why was that ever accepted? I don’t care what size it was before milling. If I buy a 2x2 I want a 2x2.

They were when the name was made, but due to changes in the manufacturing process, they aren’t anymore. The name stuck, though.

https://www.popsci.com/two-by-four-lumber-measurements-explained/

So don’t fret. The next bundle of 2-by-4s you pick up in the hardware store are certain to be the exact same size: 1.5-by-3.5 inches.

So they can measure precisely, after all

Ans yet this piece is 1.28

1.28 is the new

21.5

It’s due to the milling to square it.

You can get rough cut 2x4 or 2x2 or anything that are actually that size but by the time you trim and square it you will end up at the measurements sold in big box stores

Edit: I mean the size they used to be in store, not OPs version :(

I think this commenter is trying to say that the nominal size of a 2x2 is 2" by 2" (and it looks like they typo’d nominal to “normal”)

The actual size of a 2x2 is 1.5" by 1.5", and OP incorrectly calls these dimensions nominal

It was done for largely sensible reasons.

https://youtu.be/WaJFudED5FQ?si=7j005FmfJVr_JQL_

In short, a 2x4 was originally 2x4 inches, full stop, but it was found that this size wasn’t necessary for the strength being applied to them in construction. We were wasting lumber for no reason. They went through a few cycles of sizing down as the actual needed strength was understood better. The naming convention stuck, though.

Here is an alternative Piped link(s):

https://piped.video/WaJFudED5FQ?si=7j005FmfJVr_JQL

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I’m open-source; check me out at GitHub.

It’s weird because it’s the size of lumber BEFORE smoothing the edges. Manufacturers take this inch a mile and the 2x4 (as well as all other dimensional lumber) has gotten smaller and smaller.

Even if it was 2" from the lumber yard, it would shrink or expand quite a bit depending on the moisture content. Expecting natural products to be an exact size would be crazy, especially when talking about construction lumber.

Now this is a very extreme case, but it was probably milled to 1.5" soaking wet, and shrank a bunch after drying out on the rack. That’s also a big reason why they’re all warped.

O that’s the size before planing.

Is nobody gonna call out OP for wearing socks with sandals? …and, ostensibly, while preparing to do carpentry?!?

That’s like a cardinal sin squared!

Jesus did it

Not in socks

No need to crucify him for it.

In the Garden of Gethsemane, the only sin he saw that gave Jesus second thoughts of dying for our sins was socks and sandals.

Can’t you see those are safety sandals. And just like safety squints, are approved PPE across the whole 3rd world industrial sphere. OP will be perfectly safe.

Nope. Definitely dead.

Nah nothing wrong with wearing socks with sandals when you’re home. Do what ever the hell you want.

But I do agree with wearing proper footwear while doing dangerous things.

Oh absolutely. I wear socks with sandals because my soles sweat and make my sandals sticky.

But yeah, wear proper attire for the work you do!

Steel toe capped crocks

I love this idea. I’m not even sure why, I don’t own crocks.

At least the socks aren’t white.

I regularly wear socks and sandals along with shorts and a sweater.

There was also a time I went to lunch with that plus a lab coat and hairnet.

Sounds like a Rick and Morty episode.

I don’t condone it, but I’ve done something similar once in a Boy Scouts meeting as a scout. Had sandals on and I don’t remember the full meeting, but at one point we were chopping wood with an axe. I did it, but that’s not my brightest move. There was also a time where I was getting my metalworking badge and entered the forge one time for a kinda free time work on your project thing with shorts on by mistake. Nobody stopped me in either case. This wasn’t pre-2000s, so I’m not sure how I got away with either event considering safety is usually taken much more seriously nowadays.

My COVID home-improvement project was hardwoods. Something like 1000sqft. Never did it before. Did 90% of it wearing no more than basketball shorts and flipflops. W/e. Only a few toe injuries.

Well if it was only a few. /s

That’s only 30% of toes, unless we’re going by overall volume.

don’t forget the unbranded Chinesium calipers.

Mitutoyo or bust.

My toolbag calipers are cheap hardware store ones. They’re accurate enough and I’m not out much when they inevitably get damaged or lost.

For a machinist yep. For home gamers, a waste of money. They don’t have the knowledge of where and when to use them nor the skills to get accurate repeatable measurements. So for OP’s use whatever CCC, (Cheap, Cheerful, Chinese), caliper he’s got is good enough.

It’s the definition of “nominal size is what ever we say it is” that pisses me off. Buying wood/lumber is the worst offender of Nominal sizing, but even metals are getting worse. I used to buy a round bar of say, ASA1018 and it would be +0"/-.002". It’s now +0/-.006", (that’s +0/-.05mm and +0/-.15mm for those living in Boca Raton). At the end of my career as a toolmaker I was often forced to purchase oversized stock and waste time turning said stock into the actual sizes required.

I can accept the poor quality tools that might be off by a few hundredths, but using imperial on precision measurement devices is unforgivable.

Um, wait. I would think that violates some sort of law (but I guess maybe we haven’t codified this?). I mean, building plans expect standards in materials, right? So how can a building meet codes if the materials are not within the expected specs?

Agreed, seems like some kind of weights and measures violation.

I’m going to guess they can get away with this because 2x2s aren’t intended for structural use. I’ve never built one into a floor, wall or ceiling.

Used for furring strips everywhere. Line a block wall with them and sheet it for example.

To someone from central europe it’s always weird how houses get build from wood in the US. 😅 I imagine you can hear ~everything happening ~anywhere in the house?

Depends. The cheap houses, yeah, there’s as fair bit of noise, but you can’t hear everything. From downstairs, you can hear when someone walks across the room above you, but not when they’re walking in other upstairs rooms. And from rooms on the same level, you can hear if someone is talking loudly in the room next door, but not enough to make out what they’re saying unless they’re yelling.

Well-built houses or buildings made for occupancy by multiple families usually have better sound insulation between the rooms/floors/units, so it’s not always an issue.

Edit: the plus side to that is I know all the noises my house makes at night, so as a light sleeper, I know when something is wrong in the middle of the night, and I only need one decent sound system for the whole house, which is great for listening to records while doing housework.

Not really, unless the house was built incredibly cheaply with thin studs and crappy drywall.

Wood is pretty decent at blocking sound – it the voids between the studs that’s an issue. Filling them with sound deadening insulation solves that problem.

It’s not as good at blocking sound as a masonry wall obviously, but it’s “good enough” at a fraction of the price.

it’s extremely common for americans to dismiss apartments because they simply cannot fathom the idea of housing that actually blocks noise, it’s one of the primary arguments i see used against denser housing.

Yup. Over here in the Western US, nearly every apartment is built as cheaply as possible and run by slumlords that will do everything that they can to refuse to return deposits. Painting over bugs and black mold between tenants is the norm, in my experience, not the exception. Add to that that insulation between apartments is scant, if present and frequently there are no physical barriers between apartment building attic accesses (in every top-story apartment that I’ve been in, it would be easily possible to gain access to others’ apartments via the attic and the attics also act to channel sound between all top apartments).

I want to say that stick-built homes are really not so fragile as people seem to think. There’s tradeoffs, of course, and ways to build them that make them uncomfortable at best and blatantly unsafe at worst. That being said, they’re pretty sturdy, fairly easy to repair and modify, and relatively quick and cheap to build.

It’s a big improvement from making them from straw.

I spent a few nights in a straw bale home, wanting to experience what they were like. They are incredibly quiet. Each bale is 1.5 ft of soundproofing/insulation. The loudest part of the house was the clock ticking. The house was heated by appliances such as the refrigerator and water heater. A local monastery built several to rent out for people wanting a tranquil contemplation.

Would you call that a “structural use?”

Structural use means load bearing. So no.

Furring strips are used in plenty of places, I provide one example where it is used in most residential homes to support drywall.

Is it not structural if it’s holding ceiling drywall…? So why are people still bickering that walls aren’t structural when they still hold drywall up…?

If it’s part of a code wall detail, would that not be structural…?

What’s with the pedantism over something like this to try and save face over not knowing what a furring strip is?

No, that’s is not structural.

Structural means it’s intended to support and transfer loads in a way that cannot be safely removed.

Since neither the furring strips or drywall are part of a structural requirement, they are not load bearing.

Drywall is structural, when used on block walls it helps provide lateral support.

This is why being pedantic usually backfires.

Drywall is inherently structural.

Regardless. It’s furring strips, you want to argue furring strips aren’t used in structural applications? They are used in all three applications the person said they haven’t used them in. They also claimed to be a wood wroker elsewhere, so I don’t see how they would use anything structural anyways….

Furring strips and drywall don’t count as load bearing. Structural means that it carries the weight of the overlying structure. Basically if the building falls down if that element is missing, it’s structural. So staircases for instance are almost never structural. Many interior walls are not load bearing so they can get knocked down without consequence. You can also split a room by building a wall that won’t be load bearing.

Furring strips and drywall don’t count as load bearing.

Except for the thousands of use cases where they are used for lateral bracing to support the structure….

Like in shear walls… strapped drywall ceilings… load bearing walls….

Yes they can be used non-structurally, I’ve never claimed otherwise, yet you are ignoring the fact that they can, and are used in load bearing structural applications……

That was one example, you can also strap roofs to install sheet metal cladding. Is that not structural? Strap a ceiling? There’s a ceiling use for you.

I figured if I gave you a real world example you could do a little research of your own. Even googling 2x2 will get you a big box store furring strip page. You should know what furring strips are if you are in the industry.

No, that’s not structural since the furring strips are not integral to load bearing capacity of the structure.

In your sheet metal example, they are only there for visual reasons - to help keep the roof flat. The roof can be put down without the furring strips. It might bend, but it still function as a roof.

The roof can be put down without the furring strips. It might bend, but it still function as a roof.

What…? Roof trusses go parallel with the length of the cladding panel, you require furring strips on the perpendicular to install them. Just like in a wall with the studs vertical, you need horizontal furring to install them.

These required larger furring strips due to truss spacing.

Furring strips are not visual lmfao. They are structural components in a lot of assemblies. Without knowing the assembly you can’t say if they are or aren’t structural, that’s the entire point I’ve been trying to make here. You aren’t the quickest one are you? I’ve pointed this out multiple times. There are thousands of use cases where furring strips are structural. To say they aren’t structural is fucking asinine lmfao.

Those aren’t furring strips in that photo. That’s dimensional lumber. In this case, those spans are large enough that they require the strength of actual lumber.

Sounds like the situation here… good call

It’s probably 2x2PT or something. There are standards for board widths.

The 2x4s that have been sized this way do meet structural code. It was found that a full 2x4 is way over spec’d for what they were used for, so why bother wasting extra parts of the tree?

Pretty much everything built with dimensional lumber in the last century has been done with undersized 2x4s, and it’s fine. The name stuck for historical reasons. Companies that build houses and order this stuff by the pallet all know what the real size is, and so do building inspectors.

Rough 2x4s were 2" x 4". Then we started finishing them for better consistency, taking about 0.5" from each dimension. Later we started using saws with narrower kerfs to have less loss due to saw blade width, better cutting and planing systems so the rough size could be smaller and still have the same finished size, then they lowered finished size some more.

These are even smaller than that. A standard 2x4 is 1.5x3.5.

deleted by creator

Thanks for the explainer.

Pretty much everything built with dimensional lumber in the last century has been done with undersized 2x4s, and it’s fine.

It’s fine, folks. Nothing to see here.

It being ugly has absolutely fuckall to do with the structural integrity

What part of this has to do with dimensional lumber?

You simply change the expected specs…

2x2PT has been 1.25x1.25 for as long as I can remember (10 years or more). It’s only the pressure treated deck stuff for railings. This does not apply to the rest of the 2x lumber, as those are still 1.5 actual. I got Simpson corner 2x2 brackets for crazy cheap way back but ended up not really using them. The 2x2s are warped to hell and a ripped 2x4 was too big in the original 2x dimension.

I’m wondering if it’s a regional thing? I just looked online for pressure treated 2x2’s and all the ones I’m seeing (home hardware, home depot, advantage lumber, etc) list as actual being 1.5x1.5

That’s possible. I just moved from CA to MI 2 years ago. I know they were 1.5 then because I built alot of props and temp walls with it. I was reusing a 3d printed joint I designed to make a garden trellis when I noticed the wood didnt fit like before.

Is this pressure treated or common?

Why is 2x2 meant to be 1.5x1.5 and not 2x2?

Premill size vs sale size. Something like that. Probably not the correct term.

Similar to how steak is measures in precooked weights.

2x4 is the rough cut dimensions from the sawmill. They end up smaller after drying (wood can hold a lot of water) and planing.

*Planed/straight wood versus raw lumber. It threw me off when I first started building stuff and summed that a 2x4 was actually 2"x4" in all my measurements/plans

*Or it would be straight if you’re lucky and don’t pick from the top of the bin at Home Depot

The old * uncooked weight

TBH that looks like a furring strip, not dimensional lumber

It’s possible they stocked the wrong thing, but it was rung up as Pressure-Treated so maybe they applied the wrong barcode?

That green tint means it is pressure treated. Just take it back (this time bring a tape measure.)

And clip it to the belt loop of your khaki cargo shorts like the rest of us weekend warrior dads 😂

I usually bring my 9ft magnetic tape from my car’s ceiling and my 4" brass fractional caliper from the glove box into the store but always end up prowling the lumber section for the loose tape measures. Wouldn’t want to look like I’m stealing, right?

He probably bought “five quarters”

It’s still a bit small, but pressure treated being a little smaller than framing lumber is not necessarily a secret:

I appreciate you covering your open toes, safety socks so you’re compliant.

This was pre-job time :) Testing a 3d printed joint with it when I noticed the wood was very undersized.

How is it in countries using the metric system ?

in France :

https://www.mara-materiaux.com/bois-de-charpente/8094-lambourde-38x63-mm-long4-m-traite-9202001090740.htmlLAMBOURDE 38x63 mm long.4 M TRAITE Unité de vente : le mètre linéaire 1.42 € /m

5.68 € /(4 m)So, this is aprox ($6.?) for one “…2x3x(~13ft)…”

(treated wood)

… verry expensive, yet, upfront size disclosure.Pretty much all of Europe lists wood in exact size of the cut that you get. It sounds highly illegal to call it a 5x5cm piece of wood and sell some other random smaller size.

Thank God freedom units give us the liberty of doing away with that commie nonsense.

deleted by creator

They don’t even send back the garbage pieces, just restock if they get returned

Nothing is immune to shrinkflation aka merchant gouging

What is your definition of gouging

Highly relevant when topically adjacent to woodworking.

Increasing prices just to fill corporate pockets, or keeping prices elevated far beyond the market necessity

This has nothing to do with shrinkflation. Just an oddity of the US lumber sizing.

Looks oversized to me, that’s 3.25 cm x 3.25 cm, looks like they could take it down by 40% and still call it a 2x2 😇

Is their entire stock like this every time, or just this one batch?

Entire stock as of 5/6/24. I didnt even notice it was smaller than usual, busy trying to find the only-slightly warped boards.

Good lumber these days is becoming hard to find. I think it is mostly due to the lumber companies trying to pump out a ton of lumber to meet demand.

I’d say it’s degradation of the market’s quality after all the forced cuts we took in 2020

Nah, lumber was already garbage quality at the big box stores before Covid.

Maybe

I just know quality is down and price is up

5/6/24

Do you live in future? Today is 08.05.24.

Good thing you checked, that’s ridiculous. If I’d cut a dado for some mixed stock and found out some of them were 1 & 1/3 instead of 1 & 1/2, I’d be pissed.

For a dado, you’d better measure every board.

But in reality, if you’re looking for a perfect fit for construction lumber, you’d also better let it dry out for a week before measuring and fitting, cause it was probably 1.5" soaking wet from the yard, and shrank a bunch.

There is a lot of manufacturing deviation with lumber. If you are that picky maybe you could try talking to one of the associates. They tend to know the best places to look and they may even help you measure.

I worked construction in the early 2000s and there was no variation in lumber dimensions.

Go to Home depot and measure

Unfortunately I can’t time travel. The fact has changed.

Dimensional lumber has negligible variance in width/depth most of the time which is why it’s called that. It’s really the length that’s a crapshoot. Gotta love when you buy a bunch of 10’ planks and a couple are a few inches short

Well, if your dadoing your probably not using soft wood dimensional lumber….

I’ve found some applications for it, honestly.

I made a work bench with oak 4x4s for legs and dado’d in pine 2x4s for the cross braces. Nice and sturdy with a good enough fit and no movement I noticed over the past 3 years.

Top comment, this. This is gonna be my default when folks ask about dimensional lumber sizes in the future

Beat me to it!

RIP Jack Nance and Ed Wright.

Here is an alternative Piped link(s):

Fire Walk with Me - 2x4s (Deleted scene)

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I’m open-source; check me out at GitHub.