I just stopped a failing print and noticed some weird extrusions happening (not english native speaker, also I’m a 3d printing noob, don’t know whether that’s the right word). You can see it in the image. Any tips to improve printing quality?

I’m printing on an Ender 3 V3 SE. This print was with standard settings.

EDIT: as a clarification, this isn’t why I stopped the print. It failed to adhere to the print plate at some spots. Redid my z offset and hopefully that solved it.

It’s either over extruding or a bed level issue. First level bed again and if it still happening calibrate your extrusion flow. Since you had adhesion issue, probably just bed leveling will solve issue. If bed is well leveled and still have adhesion issue, clean your bed with basic soap and hot water (and avoid touching bed with your hand as much as possible)

If you haven’t yet, I recommend following some calibration guides for your filament brand / style / nozzle. I’ve been using https://github.com/SoftFever/OrcaSlicer/wiki/Calibration in conjunction with the Orca Slicer software, though I know that’s a derivative of Bambu software and may not directly translate to your Ender. But something along those lines should help to at least make sure you’re working from a proper baseline.

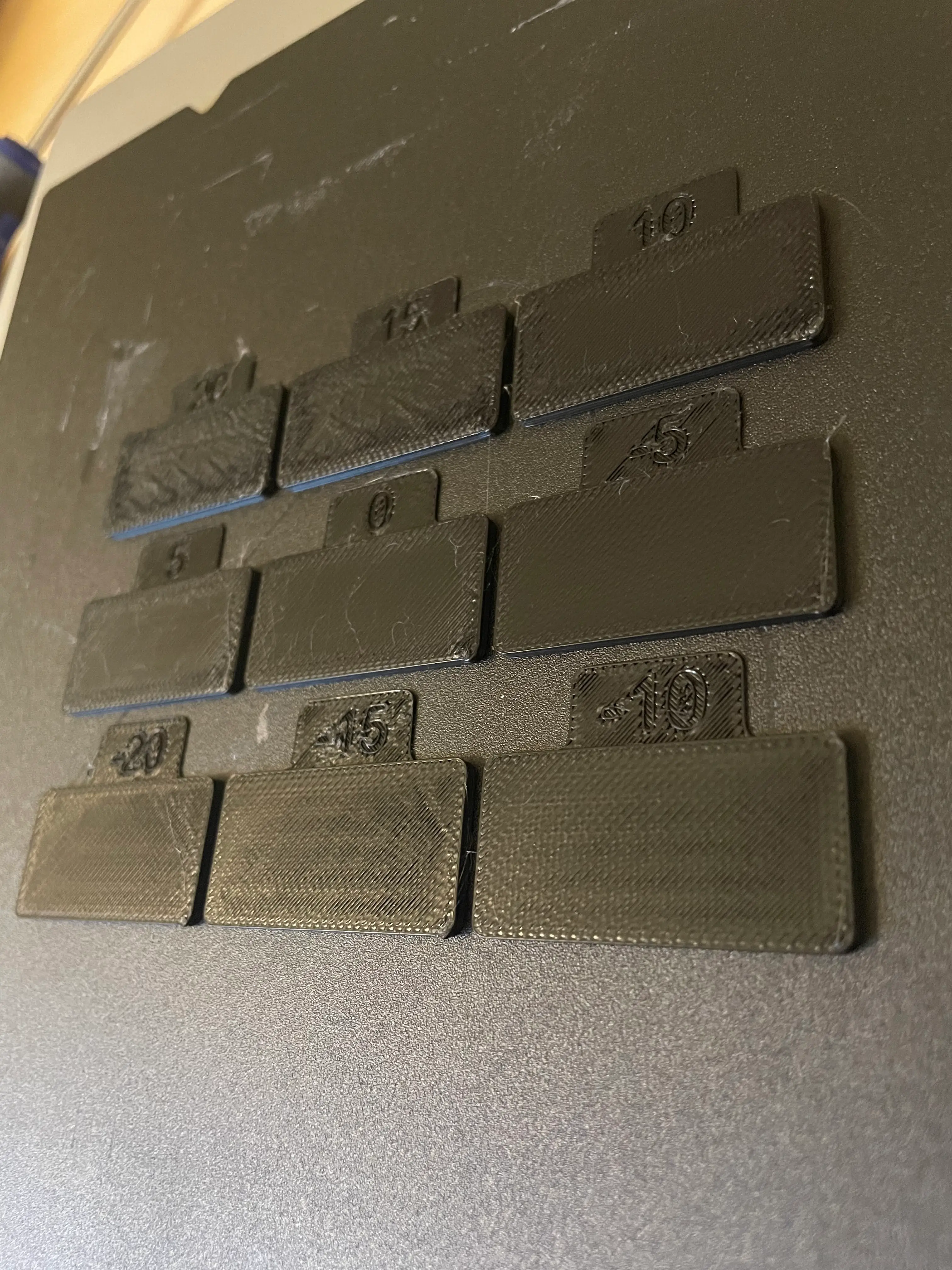

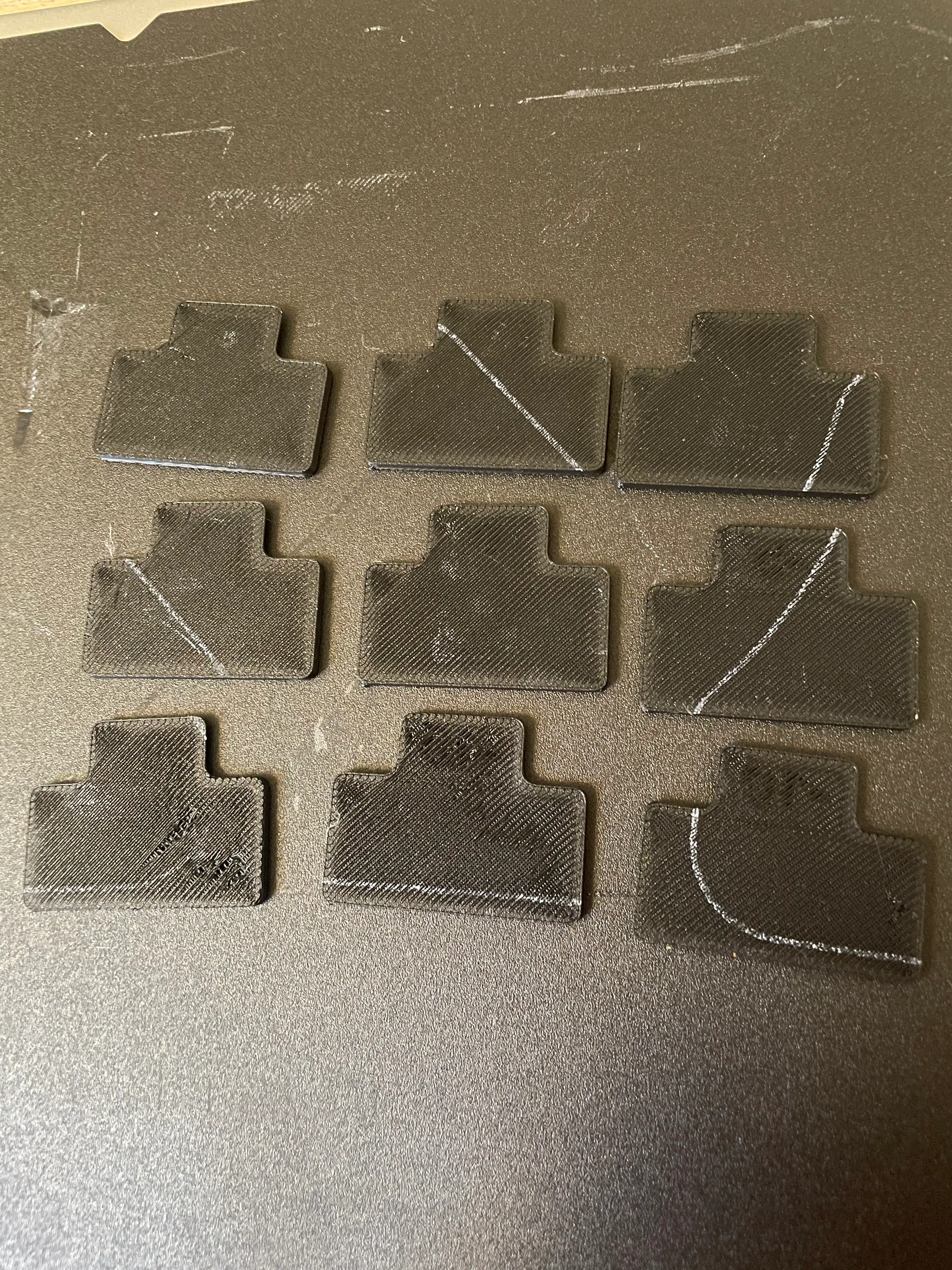

Just installed Orca Slicer and did the calibration run. Very interesting results.

I flipped them over in their respective positions, i.e. -5 is still in the middle right.

What I interpret from those pictures is that I need different values for the first layers and the layers above that. For the top layers, -5 and -10 look very good, for the first layer +10 and +15 are looking good.

And yes, I know my printbed is kinda fucked, I already ordered a new one. Surprisingly, it didn’t impact performance that much. In the last weeks, I had no failing prints whatsoever with the standard settings. Sure they weren’t looking pristine, but usually that didn’t matter.

I was gonna say the z offset is too low, so the filament is getting squeezed around the nozzle and bunching up in those gobs. Did your adjustment work?

Nope, this time nothing sticked at all. Washing with soap as a next step, as that helped last time I had sticking issues. Will try again tomorrow as it’s getting late here.

deleted by creator

PLA, that was 60C, as that is the standard in cura. I’m mostly using standard settings.

Yeah, a warm soapy wash is definitely a good step to include here. Let us know how it comes out

Yep, together with removing some junk from beneath the print bed and recalibrating that solved the adhesion problem.

Oh, good to hear!

Also, how much are you adjusting, in terms of steps?

I don’t know what you mean by that :( what steps are you referring to?

Oh sorry, how many hundredths of millimeter are you are adjusting at a time. You should just make small adjustments and try them on a small first layer test print. But I guess you’re live adjusting, so what I said doesn’t make a lot of sense

Just tossing some more ideas in the ring:

Make sure there isn’t a piece of plastic stuck to the heater under the bed - happened to me a couple times and it causes a very sudden high spot that manifests as a very thin spot on the first layer or a hole if it’s bad enough.

If your bed is PEI, I find that fresh from a dish soap wash or isopropyl wipe down isn’t always the best adhesion - but I find that printing just the first layer and then peeling and restarting can give an even better adhesion since the first layer picks up any contaminants very well, but that doesn’t seem likely to be the root cause here.

Are you able to watch up close while it prints the first layer? You should be able to see whether the plastic is still coming out of the nozzle when it hits the bad spot. You should also be able to easily see if the plastic is still coming out but balling up on the nozzle, or if it’s getting squished too much and having trouble due to a high spot, or if it stopped extruding for a moment and only pulled the last bit of extrusion into a thin hair while not pushing out any new filament even though there’s space under the nozzle. That will help narrow down the issue a lot between a bed leveling issue, adhesion issue, nozzle clog issue, or other extrusion issue.

Just looking at the picture, because it happens around the same spot as it goes back and forth, it feels more like something around that spot on the bed - either a high spot or a dirty spot. But watching what happens up close and how the filament coming out up close behaves should help determine.

Turns out there was some stuff under the print bed! Thanks for that info. Had to recalibrate after removing them, and that got me the first successful print again. Unfortunately couldn’t really look between the print head and bed, as it’s a really weird angle and there’s very little to see. Will try again when I have another spot for the printer to put.