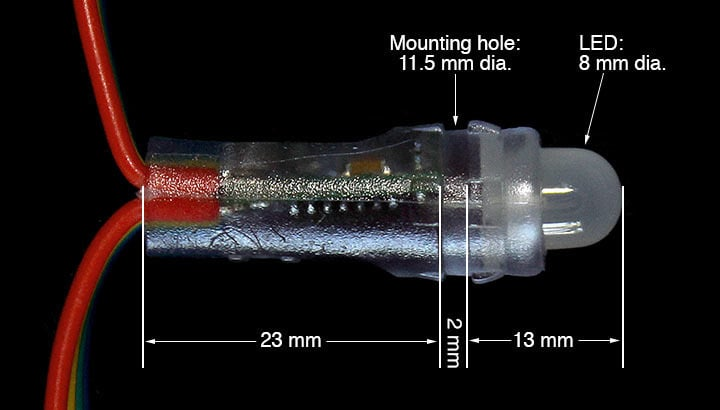

I’m in the process of replacing all my single-color christmas lights with addressable RGB LEDs, but the 12mm “bullet” form factor of them is different from the traditional incandescent mini lights, the 5mm wide angle LEDs, etc.:

You’d think they’d make C6/7/9 bulb covers that attach to them, but I have yet to find any for sale, anywhere. As such, I want to 3D print some, along with 12mm bullet pixel-sized replacements for my snowflake lights:

What’s some good filament I can get that will be reasonably clear and stay that way (without yellowing or getting too brittle) for several years’ worth of Christmas seasons, despite UV/rain/cold exposure?

(Bonus question: anybody know a good way to model the facets in those “strawberry” lights? The C7 bulbs on Thingiverse, such as this one, are all smooth, LOL.)

Edit: by the way, to be clear (pun intended): I don’t need optical clarity like the lens guy; scattering the light is fine. (In fact, doing that on purpose is kind of the point of modeling a faceted C7 bulb instead of a smooth one.) I just want to make sure that whatever part of the filament that doesn’t manage to be transparent is white, not tinted some dingy color.

I do happen to have some Inland “natural” PLA laying around and did a test print in that. It’s not too bad – only a little bit yellow at the wall thickness I’m using – but I fear for how it will hold up over time.

I would just run clear PETG to see how it does, and keep the model files on hand in case they need to be replaced. PETG/s UV resistance is decent and will certainly last at least a continuous year or two in most exposure situations, and it is by far the most cost effective and easiest to print; it’s cost effective enough that even if they begin to fail after 2 years, you can print more. and at <$20/kg, it’s the cheapest to experiment with.

Polycarb will be more UV,thermal, and impact resistant but not sure it’s worth the added cost and printing difficulty for this kind of project. The one major benefit it would have is higher light transmittal vs clear PETG, but it’s really not by much, and probably not worth the $15+/kg premium over PETG.

Any opinion on specifically which clear PETG I should get?

Never had Overture steer me wrong. I use Overture almost exclusively for ASA and they’re reliable, don’t see any reason why they wouldn’t work for PETG too.

Their cardboard spools aren’t Bambu AMS compatible (or compatible with any filament solution that relies on spool edge rollers), so keep that in mind.

Inland is Microcenter’s in home brand and I’ve heard good things about them too.

Is there any reason to think Creality would be a particularly good choice because it matches the brand of my printer? (If not, I’ll get the Overture.)

Not really any correlation. Plastic filament is plastic filament. About the only outlier would be Bambu with their rfid AMS identification system. But even then, I’ve put 5 different brands through my Bambu printer and honestly, Bambu filament has performed the worst lol (it’s more wet than most out of the box and needs drying).

?

I’ve run Overture cardboard spools in my Sunlu filament dryer directly into my printer many times with no incident. It has rollers for the spool edges, no center axle. And other brands’ cardboard spools as well.

Ah. Well bambu ams has issues with their rollers slipping on cardboard spools unless you print a clip on ring that covers the outer edges, only because bambu uses the rollers to backdrive the spool when unloading. Not so for basic feeders

Overture. IDK where Creality gets their filament but I guarantee they don’t make it themselves and printers are their business, not filament.