Casey

- 1 Post

- 16 Comments

Got the part in but my wife went into labor. We had a 8 lb 7 oz baby!

Obviously this is going to delay the progress of this saw project.

I did want to mention that the bent washer isn’t very “bent”. I’m going to figure out how to provide measurements once I can get to focus on this again.

I promise I’ll get y’all updates at some point.

Still waiting on the part.

USPS says it should be here tomorrow (05/10/2024).

I’m looking forward to using this thing for so many projects.

Still waiting on the part. USPS is late with the shipment.

I won’t let you down. I’ll keep ya posted. Thanks again for all the help!

I am reluctantly ordering a single wave washer here for $9.76 if you include shipping:

5140032-75 Washer, Curved, 10.1 X 17Mm - Dewalt®

I checked all of my local hardware stores. I think Lowes usually has these, but they said their small parts vendor hasn’t come to restock anything in a long time and they weren’t sure when they would be coming back. All other hardware stores in my area didn’t have them or staff wasn’t very helpful.

I will keep everyone updated. I hope this is the last part that I need to order online. I’ll try to do a summary video when I’m done because I haven’t found many that really get into this level of detail on repairing this specific issue online. I’m just glad I’m keeping this thing out of the dump and I hope to start using it soon so I can start to build and repair some stuff around the house. Super excited about building a French Cleat system in my shed.

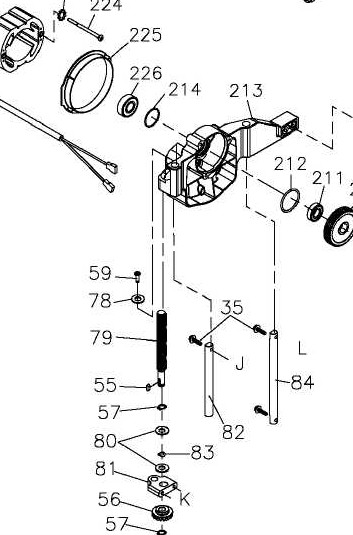

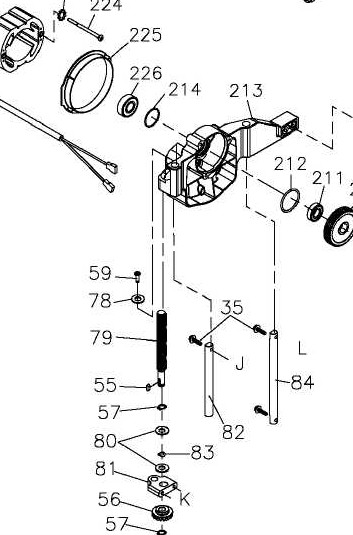

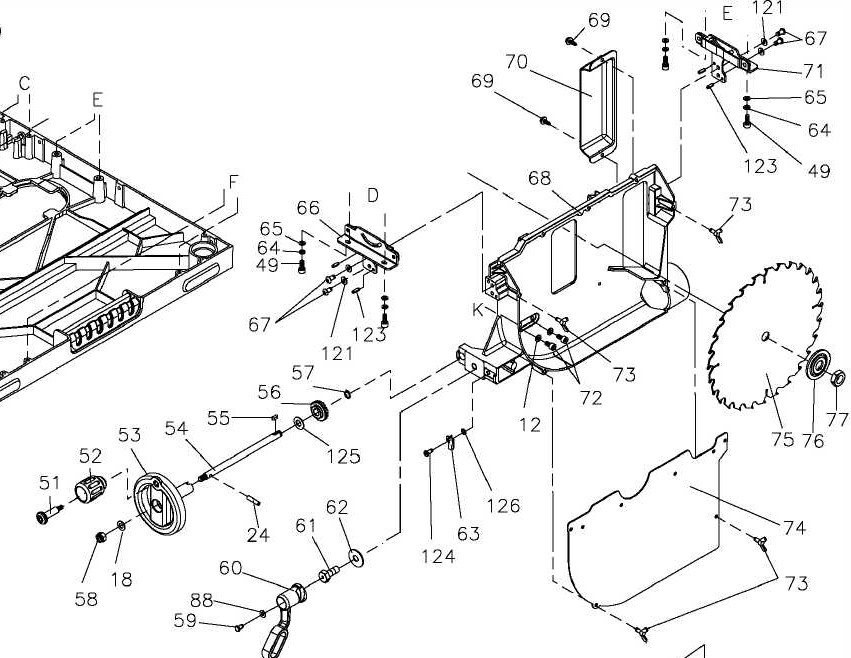

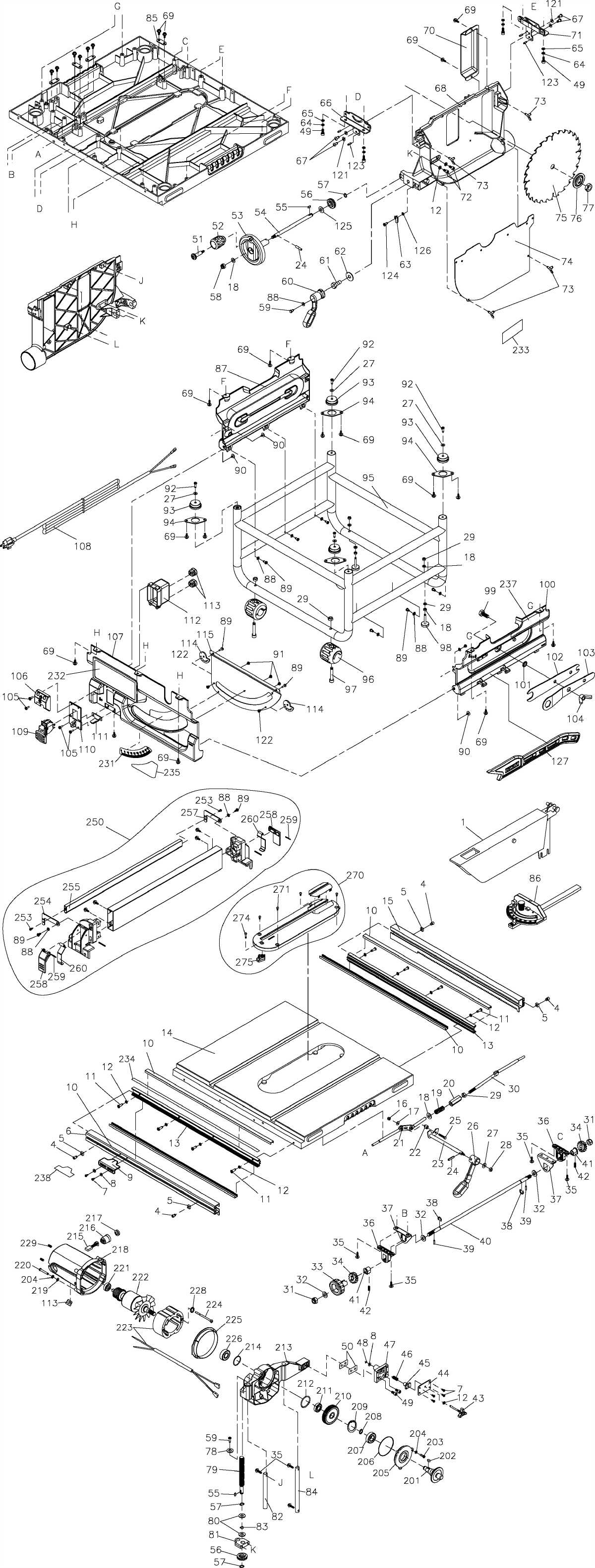

I’m looking at this part of the diagram

I’m noticing part 83 (Washer 5140032-75)

That washer appears to be bent on purpose on the linked website for replacement parts and I’m guessing that it would keep the tension on the threaded dowel consistent. I think mine is missing or it was flattened out when someone torqued the mechanism.

Upon further research that is a bowed washer, spring washer, curved washer or wave washer. Their purpose is to retain tension and it’s likely the solution to my gears binding. More can be explained in this video: https://youtu.be/sG1gSQGZQl8?si=nQhzR2a8TZUwJ5rY

That’s another guess.

Would like to get some guidance here.

Well, the screws were definitely over torqued, but it didn’t fix the issue. I tried multiple methods to get one of the screws out but had to use a grinder and a flathead screwdriver to get it out.

I think I may have an Idea what is causing the issue after looking at the gears after your advice.

Since the clanky movement really only happens in one direction when the saw is on its side I figured it had something to do with the direction of the pressure being applied by the screw mechanism.

When I put the table saw completely upside down and then tried to move the blade up and down it was very smooth.

This led me to think that there might be some movement in the gears based on the pressure that’s being applied. Watch this video to see what I’m talking about and you’ll see a gap that closes when I go in one direction and opens back up in the other.

You can see the movement of the gear at about the 1:04 mark in the video.

https://youtu.be/4J7jqrm9Sn4?si=UAGNhSC3HjRo7LS8

Any advice?

Thank you!! I always appreciate learning something new.

I’m attempting to learn what a shaft boss is so I can find it. Is there a part number on this exploded diagram that you can refer to?

It may be in the 30s or 50s (if that helps you find it)

You may be right about the tightness. I noticed that the spinning gets smoother when the saw is on it’s side as seen here in the second video I made. https://youtu.be/MdXE7IPnA6s?si=AteFwlZ1x2kFfOVt

I don’t think they are skipping. It gets smoother when I have the saw on it’s side.

7·1 year ago

7·1 year agoI just planted a bunch of driller Diakon Radishes in my front yard to do some biological tillage on all of my clay soil.

Lots of info on YouTube about doing this.

I plan to leave most of them in the ground to compost, but I plan to pull some for eating.

The cool thing about them is that pull needed nutrients from deep underground.

This is what I bought: https://meritseed.com/driller-daikon-radish-annual/

I know you can send soil to be tested by your local university extension, but how do you test for conaminents like used hydrocarbons, arsenic, lead, glyphosate-based herbicides, etc?

I am about to embark on a hobby of composting and would like to know.

DEATHPROOF